Repair to a damaged 1200mm seal diameter of a stainless steel sleeve attached to the propeller has recently been successfully undertaken during a scheduled maintenance period at a Chinese dry dock.

In-situ Machining Solutions (UK) Ltd., at the request of the company’s South Korean agent were invited to tender for the repair of the 1200mm x 350mm long stainless seal diameter which had suffered circumferencial grooving damage 1mm deep.

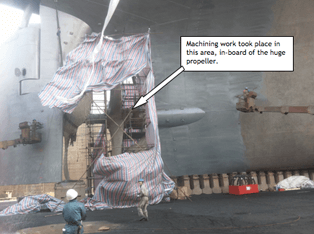

Removal of the sleeve seal assembly for off site repair was not a viable option due to the seal assembly being situated in-board of the huge 7000mm diameter propeller which could not be removed due to the time constraints and associated costs of the programmed dry docking period.

Since the propeller shaft could not be rotated due to other maintenance work being undertaken along the line of shaft, the only repair solution was to use an orbital or planetary machining system to refurbish the 1200mm stainless steel seal diameter.

Having successfully won the order, the In-situ Machining Solution’s design and on site machining team set to work in producing the necessary machinery, measuring and tooling equipment to carry out the work. All equipment was produced, tested and boxed up ready for shipment to China within a six week period.

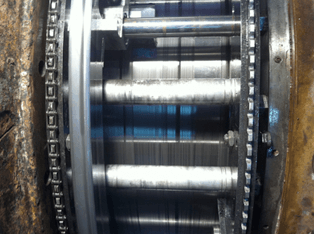

Once on site, the machining team set up the machining equipment to pre determined reference points, a series of machining cuts were then taken along the seal diameter, followed by a super finishing and polishing operation, this being standard procedure for this highly precision work the company routinely undertakes.

To remove the propeller and sleeve and to refurbish the sleeve and subsequent re assembly would have taken at least 4 weeks to carry out. In-situ Machining Solutions (UK) Ltd achieved the in-situ machining repair work in just 10 days, thus saving 20 days on the project and as a result, helped to significantly reduce the dry docking period of this super vessel with resultant cost savings to the ship owner.

All work was carried out in conjunction with our customer’s and the end user specification, inspected and passed off to their satisfaction, prior to the team’s demobilising from site.

Photographs indicate the work being undertaken.