In-Situ Machining Solutions (UK) Ltd. have recently been contracted to repair a MAK 8M43C generator crankshaft of a 2400 passenger cruise liner.

The work involved on-board machining an engine’s crankpin/big end bearing journals that had failed during service in addition to two adjacent main bearing journals which had been scored as a result of debris contamination from the crankpin seizure.

The initial enquiry to our technical department was made by a UK marine management company who indicated that this work was extremely urgent which is common in the marine industry. With this information, one of our engineers prepared all the necessary tooling, was mobilised and flew to meet the vessel at a port in Italy, hand carrying in excess of 250kg of equipment.

Once on board, our engineer carried out detailed mechanical survey of the damaged crankshaft relating to NDT magnetic particle crack detection and hardness survey of the damaged crankpin and main bearings. These details were forwarded to our client and the OEM to enable a decision to be made on the way forward with this repair.

With this information and urgent nature of the repair, In-Situ (UK) Ltd. were instructed to provide 24hr coverage, to enable this crucial work to be completed whilst the ship sailed between ports of call in the Mediterranean Sea. At this In-Situ (UK) mobilised another engineer.

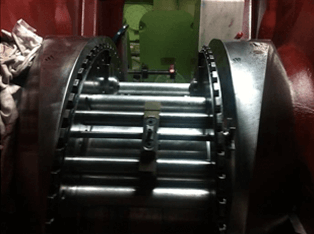

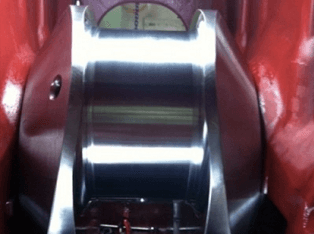

One millimetre had to be machined from the Ø380mm crankpin to make good the damage caused by the failure and a maximum 0.02mm from the two Ø410 mm main bearing diameters. Associated tooling to complete this job was orbital turning equipment, superfinishing, polishing and calibrated measuring instrumentation including a computerised level measuring system to compensate for the movement of the vessel whilst at sea. All work was carried out to OEM procedures, limits and tolerances.

This is a routine repair undertaken by the company who have an abundance of knowledge in this field, working in all corners of the world performing repairs to all types of large marine and industrial equipment to exacting mechanical tolerance and surface finishes. Orbital machining is the one of the core activities of In-Situ (UK) Ltd. with machines capable of machining up 1250mm in diameter.

To have stripped the engine, removed the crankshaft and repaired it off site and into a machine shop was not an option that could be tolerated due to the ship’s scheduling. Machining the crankpins on board as the ship sailed was by far the most efficient and cost effective means of repair.

Final inspection was carried out by the In-Situ (UK) Engineers and was supported with relevant documentation. The Maker’s representative and the Chief Engineer of the vessel also did their own inspections. The OEM who issued the machining contract to In-Situ (UK) were extremely satisfied with the way we responded and with the quality workmanship that was achieved. This was related as well by the vessel’s owners. In addition In-Situ (UK) policy is to follow up with a Customer Satisfaction Survey after a few weeks of finishing the job. This also complies our ISO procedures. On this particular questionnaire we received a 100% satisfaction.

During this repair there was with no interference to the cruise liner’s scheduling.